Powder Metallurgy Products

- Top

- Business

- Powder Metallurgy

- Powder Metallurgy Products

Search products

Automotive Parts

Drivetrain Parts

Other Automotive Parts

Product List

Bushing Family

- Parts for Industrial Machinery

The bearing body has a lubricating structure as lubricating oil is contained in the pores of the bearing body. The bearing body lubricates itself by frictional heat, so it can operate stably for a long period of time without periodic lubrication.

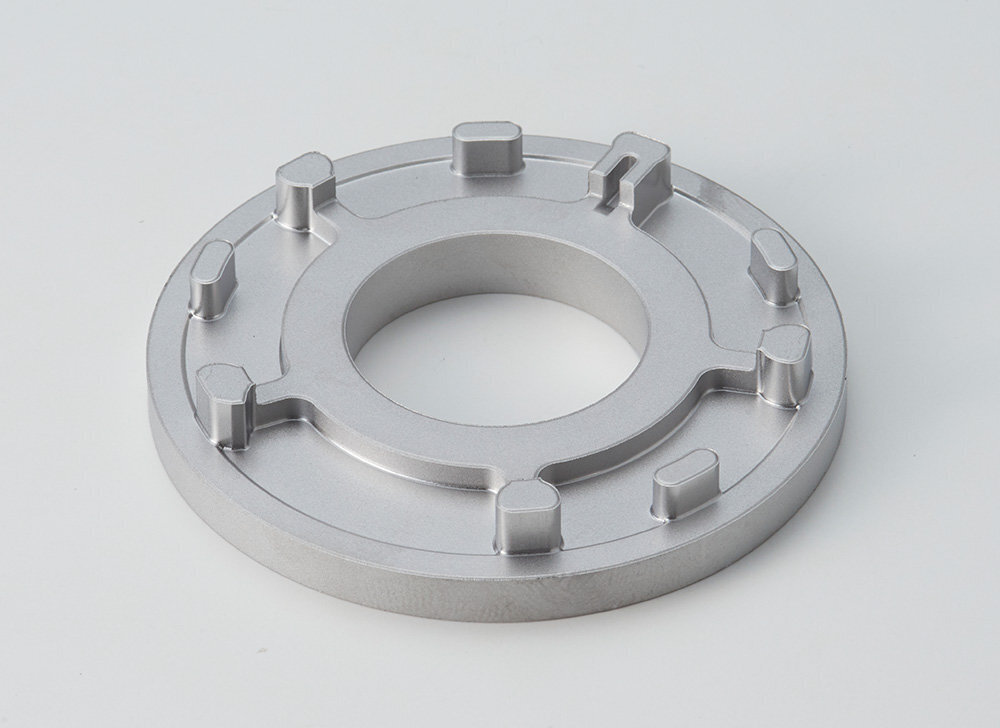

Plate

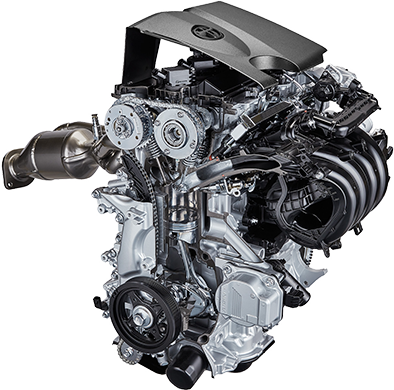

- Automotive Parts

- Engine Parts

Complex shapes are formed by a near-net-shape manufacturing technique using heat-resistant materials which are unique to powder metallurgy.

Outstanding “Plate” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

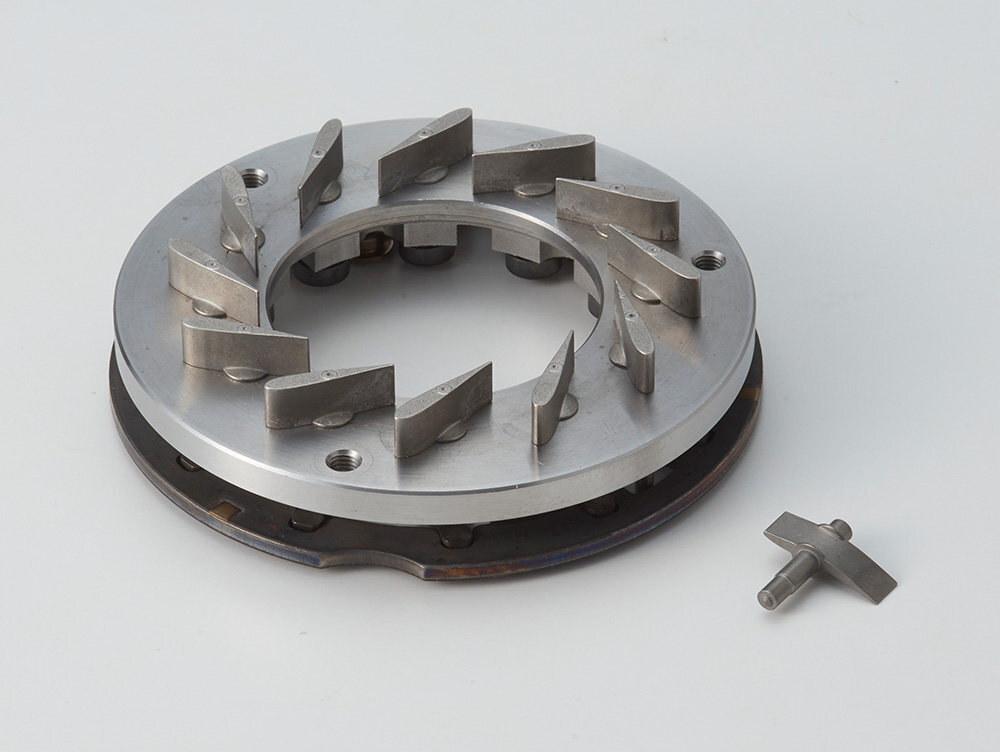

Vane Nozzle

- Automotive Parts

- Engine Parts

Using stainless steel materials that can withstand use in high-temperature exhaust air, we manufacture complex three-dimensional shapes by the MIM (metal injection molding) method.

Outstanding “Vane Nozzle” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Spherical Seat

- Parts for Industrial Machinery

Outstanding “Spherical Seat” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Shaft eccentric

- Automotive Parts

- Engine Parts

Even with complex and thin-walled shapes, high dimensional accuracy is ensured.

Outstanding “Shaft eccentric” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Sprocket

- Automotive Parts

- Engine Parts

The tooth tips are highly strengthened by induction hardening, and the tooth shape is formed by a near-net-shape manufacturing technique.

Outstanding “Sprocket” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Hydraulic Parts for Construction Machinery

- Parts for Industrial Machinery

This is a hydraulic pump part for agricultural machinery. The cost is reduced by forming the piston cylinder bore shape, etc., by a near-net-shape manufacturing technique.

Housing

- Automotive Parts

- Engine Parts

Complex inner profile shapes are formed by a near-net-shape manufacturing technique that is unique to powder metallurgy.

Outstanding “Housing” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Flange

- Parts for Industrial Machinery

This part is manufactured by the MIM (metal injection molding) method. The use of MIM process has realized a significant cost reduction in parts that were conventionally manufactured by machining.

Outstanding “Flange” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

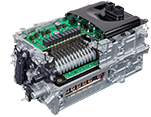

Contact Strip

- Parts for Railway Vehicles

Rotor

- Automotive Parts

- Engine Parts

Complex outer profile shapes are formed by a near-net-shape manufacturing technique that is unique to powder metallurgy.

Outstanding “Rotor” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Brake Lining

- Parts for Railway Vehicles

Piston Rod Packing

- Parts for Railway Vehicles

Grounding Brush

- Parts for Railway Vehicles

Sintered Arm

- Automotive Parts

- Engine Parts

High-precision helical splines are realized with high technical capability. The processing cost has been reduced by processing green compacts.

Outstanding “Sintered Arm” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Titanium Valve

- Automotive Parts

- Engine Parts

Titanium compounds are formed using a combination that can only be achieved by powder metallurgy, and are used in high-performance engine valves.

Outstanding “Titanium Valve” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Valve Guide

- Automotive Parts

- Engine Parts

Through research and development of materials, we provide products that meet high performance requirements for improved engine performance and environmental friendliness.

Outstanding “Valve Guide” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Valve Seat

- Automotive Parts

- Engine Parts

Although usage conditions are becoming increasingly more severe, such as the lean-burn combustion process being adopted to improve fuel efficiency and to meet emissions control regulations, we meet these requirements with the development of new materials.

Outstanding “Valve Seat” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes