Powder Metallurgy Products

- Top

- Business

- Powder Metallurgy

- Powder Metallurgy Products

Search products

Automotive Parts

Drivetrain Parts

Other Automotive Parts

Product List

Shock Absorber Product Family

- Automotive Parts

- Shock Absorber Parts

Outstanding “Shock Absorber Product Family” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Ring Carrier

- Automotive Parts

- Engine Parts

The ring carrier is cast into a piston as a base to fit the engine piston ring. Since aluminum is cast during integration, the product has a low density. In addition, since friction with the piston ring occurs, hard particles, which are used for the seat valve, etc., are also used for wear resistance.

Crank Angle Sensor

- Automotive Parts

- Engine Parts

This is a gear part for fuel injection timing. The gear angle tolerance is strict, and strength is also required because of interference with mating part.

Outstanding “Crank Angle Sensor” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Rod Guide

- Automotive Parts

- Shock Absorber Parts

Outstanding “Rod Guide” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Holder Fuel

- Automotive Parts

- Engine Parts

In order to ensure corrosion resistance, plating is applied after sealing treatment by resin impregnation.

Outstanding “Holder Fuel” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Clamp Nozzle Holder

- Automotive Parts

- Engine Parts

Outstanding “Clamp Nozzle Holder” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Plate

- Automotive Parts

- Engine Parts

Steam treatment is applied to ensure wear resistance and corrosion resistance.

Valve Case

- Automotive Parts

- Shock Absorber Parts

In order to intentionally reduce the contact area as a countermeasure against noise caused by valve adsorption, minute concave and convex dimples are formed without machining.

Outstanding “Valve Case” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Banded Piston

- Automotive Parts

- Shock Absorber Parts

The part is wrapped by plastic after special grooves are made on the outer circumference sliding portion to ensure sliding performance.

Outstanding “Banded Piston” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Special Piston

- Automotive Parts

- Shock Absorber Parts

Combining two parts eliminates the need for diagonal drilling of port holes used as oil channels, resulting in reductions in process and costs.

Outstanding “Special Piston” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Reactor Core

- Automotive Parts

- Motor-Related Parts

This is a key component at the heart of an inverter that boosts battery voltage of a hybrid vehicle and increases the input to the motor. Compression-molded individual magnetic particles are insulated from each other, resulting in high electrical resistance and excellent electromagnetic conversion efficiency.

Outstanding “Reactor Core” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Motor Core

- Automotive Parts

- Motor-Related Parts

This is a soft magnetic component called dust core, made of insulation-coated iron powders. Although a laminated steel plate is generally used for a conventional motor core, the use of a dust core provides a greater flexibility in shapes and realizes miniaturization.

Outstanding “Motor Core” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Cover Balance

- Automotive Parts

- Engine Parts

Outstanding “Cover Balance” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

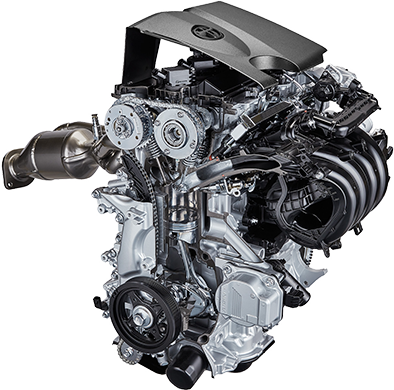

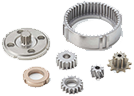

Oil Pump

- Automotive Parts

- Engine Parts

The trochoid pump profile shape is formed by a near-net-shape manufacturing technique.

Outstanding “Oil Pump” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Sensor Boss

- Automotive Parts

- Engine Parts

Heat resistance is ensured by using a stainless alloy material, and welding is possible due to high density.

Outstanding “Sensor Boss” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Exhaust Flange

- Automotive Parts

- Engine Parts

Heat resistance is ensured by using a stainless alloy material, and welding is possible due to high density.

Outstanding “Exhaust Flange” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Sintered Vent

- Parts for Industrial Machinery

This filter is used for venting castings. Since it is a sintered metal product, it is used as a filter that can withstand high temperatures.

Outstanding “Sintered Vent” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

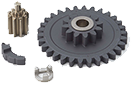

Sprocket

- Automotive Parts

- Engine Parts

Our unique warm compaction method allows us to produce low-cost, high-strength sprockets by increasing the density of low-alloy materials.

Outstanding “Sprocket” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Bushing

- Automotive Parts

- Engine Parts

Wear resistance is ensured by using materials that can withstand high-load operating environments.

Outstanding “Bushing” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Thrust Metal

- Automotive Parts

- Engine Parts

The material characteristics enable the slide bearing to withstand high load pressure in the high rotation range.

Outstanding “Thrust Metal” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes