Powder Metallurgy Products

- Top

- Business

- Powder Metallurgy

- Powder Metallurgy Products

Search products

Automotive parts

Drivetrain Parts

Other Automotive Parts

Product list of Near Net Shape

Oil Pump Gear

- Automotive Parts

- Drivetrain Parts

Outstanding “Oil Pump Gear” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Transfer Actuator Family

- Automotive Parts

- Drivetrain Parts

Outstanding “Transfer Actuator Family” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

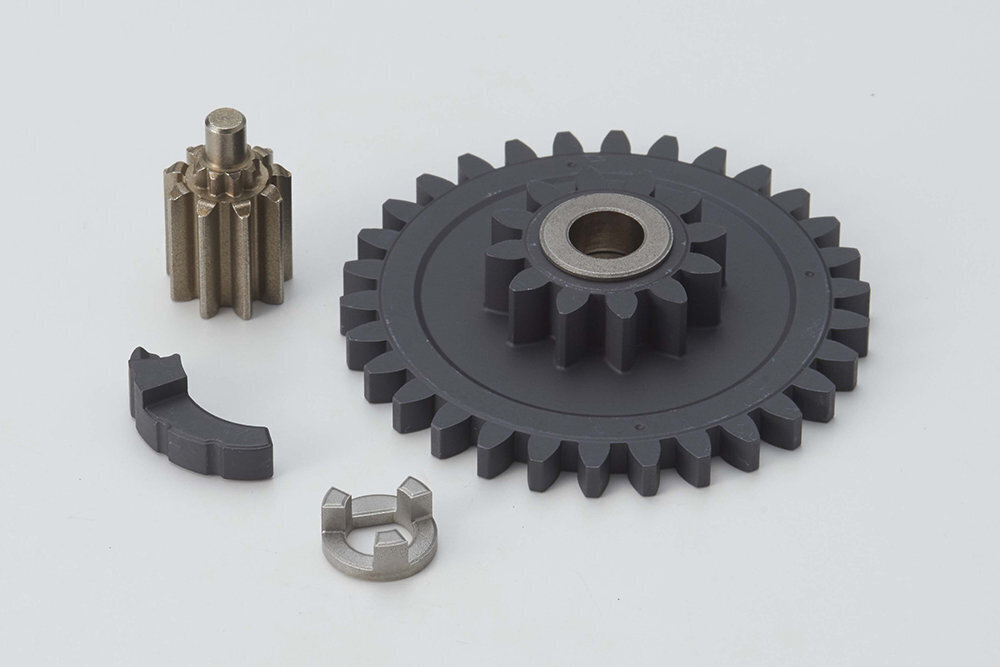

Disconnect Product Family

- Automotive Parts

- Drivetrain Parts

"These are important parts that connect and disconnect the rear-wheel drive of four-wheel drive vehicles.

The required complex shape of the product is realized by using advanced powder metallurgy forming technology."

Outstanding “Disconnect Product Family” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Control System Part

- Automotive Parts

- Drivetrain Parts

Outstanding “Control System Part” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

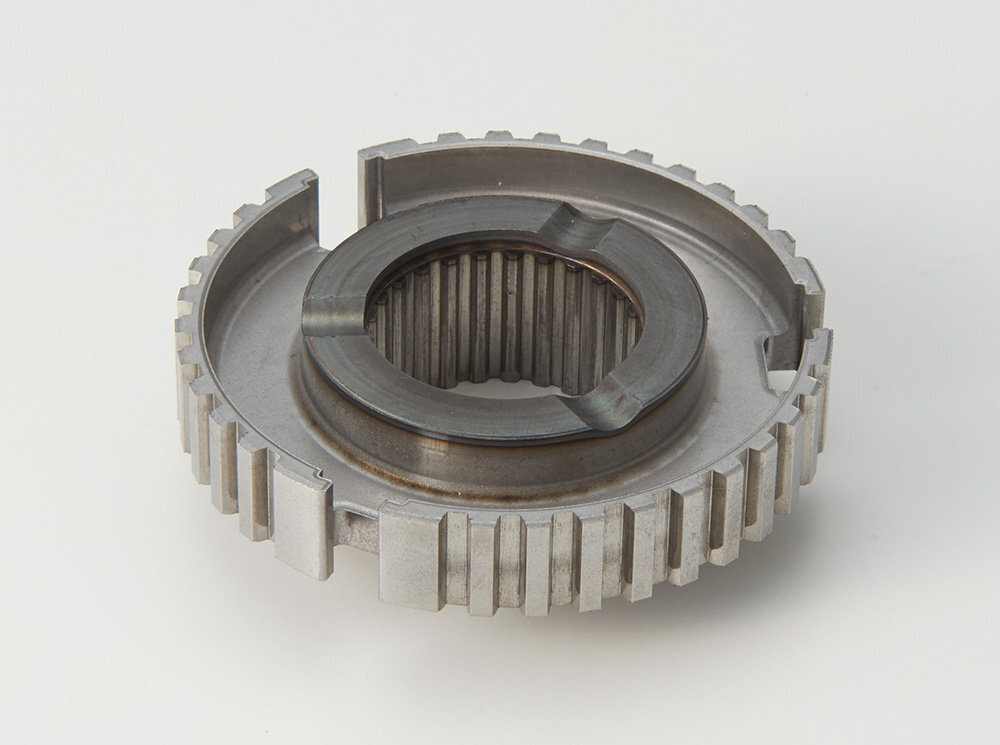

Hub

- Automotive Parts

- Drivetrain Parts

The deep concavo-convex surfaces and complex profiles are formed by net shape processing using a CNC press, contributing to reduction in raw materials and costs.

Outstanding “Hub” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Synchronizer Ring

- Automotive Parts

- Drivetrain Parts

Varied required characteristics are realized with the world's first double-layer integration technology. We offer low-cost, high-performance products.

Outstanding “Synchronizer Ring” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Body Parts (Wedge, Coupling, and Two-Stage Gear with Press-Fit Bushing)

- Automotive Parts

- Other Automotive Parts

Several products have been adopted such as gears, couplings, and wedges used for electric power seats, electric power sliding doors, and back door actuators.

Outstanding “Body Parts (Wedge, Coupling, and Two-Stage Gear with Press-Fit Bushing)” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

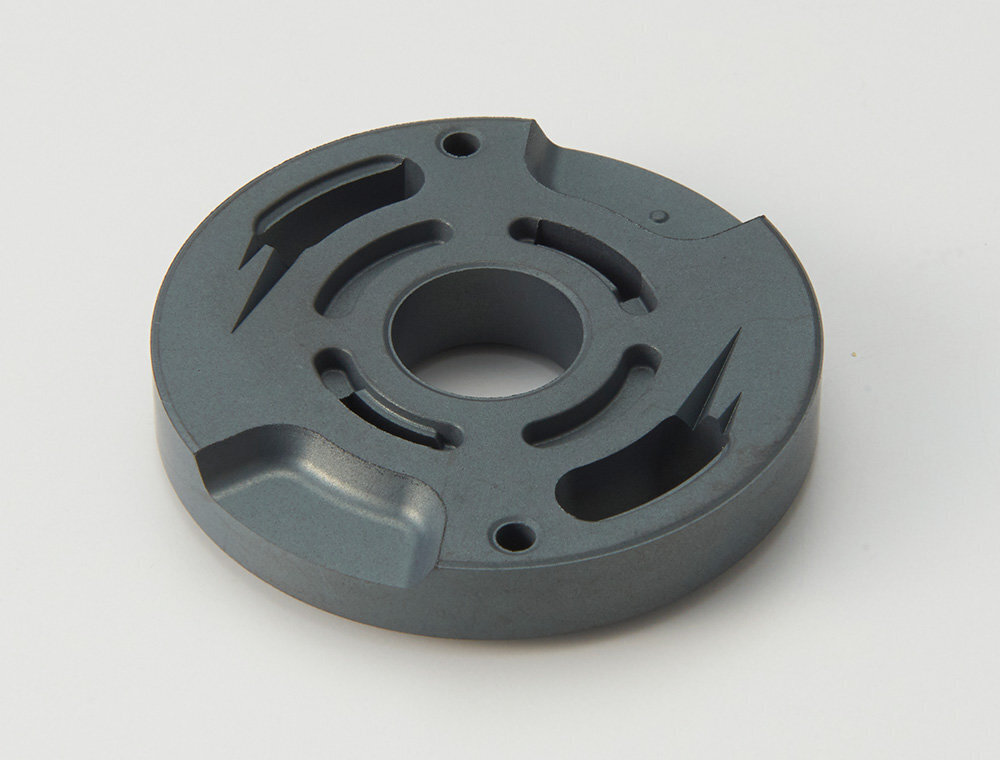

Side Plate

- Automotive Parts

- Drivetrain Parts

High-strength materials, one of our notable features, contribute to the miniaturization and higher capacity of pumps.

Outstanding “Side Plate” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

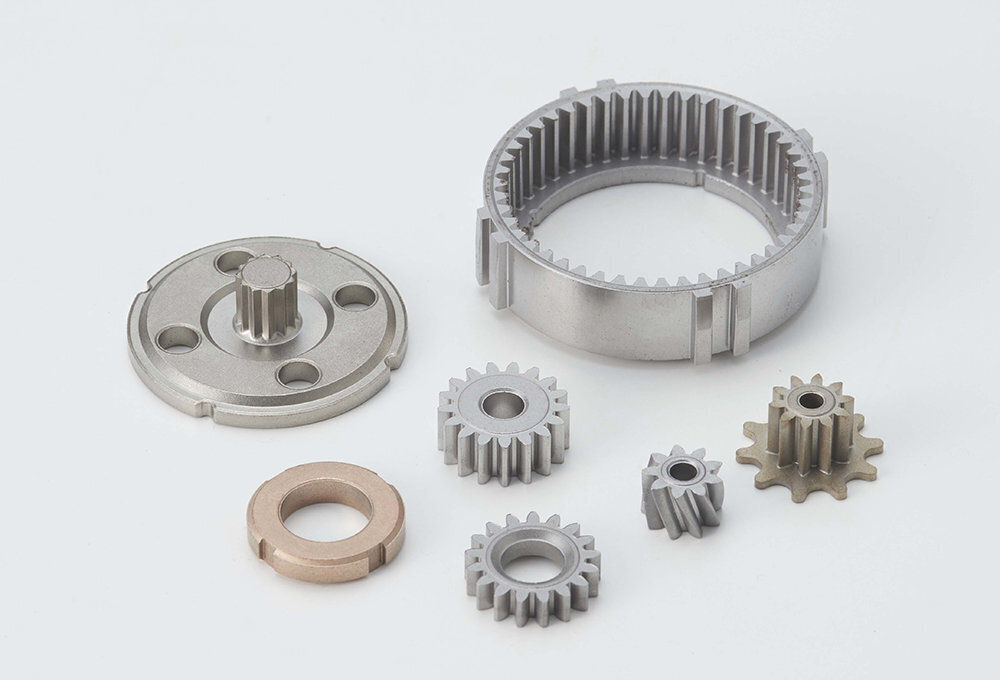

EPB Product Family

- Automotive Parts

- Other Automotive Parts

A number of gear-shaped parts, taking advantage of powder metallurgy, are also used for electric parking brake parts.

Outstanding “EPB Product Family” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Cam Ring

- Automotive Parts

- Drivetrain Parts

High-strength materials, one of our notable features, contribute to the miniaturization and higher capacity of pumps.

Outstanding “Cam Ring” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Rack Guide

- Automotive Parts

- Other Automotive Parts

The radius shape to receive the rack bar is formed without machining.

Outstanding “Rack Guide” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Rotor

- Automotive Parts

- Drivetrain Parts

High-strength materials, one of our notable features, contribute to the miniaturization and higher capacity of pumps.

Outstanding “Rotor” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Sleeve Parking Lock

- Automotive Parts

- Drivetrain Parts

Even products with complex shapes that require wear resistance and high strength are manufactured using dies.

Outstanding “Sleeve Parking Lock” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Sprocket drive

- Automotive Parts

- Drivetrain Parts

The sprocket is attached to the chain that connects the AT spindle and oil pump shaft.

In addition to high-precision, multi-stage gear sprockets, we mass produce sprockets using our original technologies such as batch induction hardening and tempering of multi-stage gears and phrasing processes.

Outstanding “Sprocket drive” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Carrier

- Automotive Parts

- Drivetrain Parts

Hollow sections can be formed by combining, sintering, and brazing parts with high precision, complex shapes as characteristics of powder metallurgy.

Outstanding “Carrier” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Composite Material

Special Processes

Tilt gear

- Automotive Parts

- Other Automotive Parts

The shaft center requiring strength is a sintered part, and on the outer circumference, the gear shape is formed by resin insert molding.

Outstanding “Tilt gear” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Tilt Cam

- Automotive Parts

- Other Automotive Parts

The cam shape is formed by a near-net-shape manufacturing technique without machining.

Outstanding “Tilt Cam” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Shock Absorber Product Family

- Automotive Parts

- Shock Absorber Parts

Outstanding “Shock Absorber Product Family” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Crank Angle Sensor

- Automotive Parts

- Engine Parts

This is a gear part for fuel injection timing. The gear angle tolerance is strict, and strength is also required because of interference with mating part.

Outstanding “Crank Angle Sensor” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Rod Guide

- Automotive Parts

- Shock Absorber Parts

Outstanding “Rod Guide” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Clamp Nozzle Holder

- Automotive Parts

- Engine Parts

Outstanding “Clamp Nozzle Holder” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Valve Case

- Automotive Parts

- Shock Absorber Parts

In order to intentionally reduce the contact area as a countermeasure against noise caused by valve adsorption, minute concave and convex dimples are formed without machining.

Outstanding “Valve Case” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Cover Balance

- Automotive Parts

- Engine Parts

Outstanding “Cover Balance” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

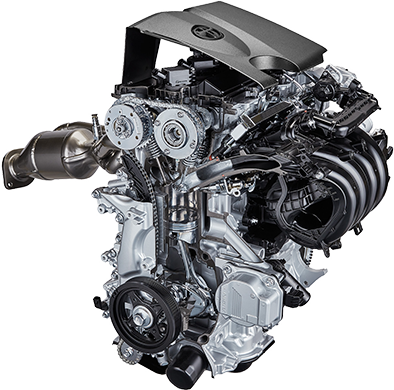

Oil Pump

- Automotive Parts

- Engine Parts

The trochoid pump profile shape is formed by a near-net-shape manufacturing technique.

Outstanding “Oil Pump” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Sensor Boss

- Automotive Parts

- Engine Parts

Heat resistance is ensured by using a stainless alloy material, and welding is possible due to high density.

Outstanding “Sensor Boss” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Sprocket

- Automotive Parts

- Engine Parts

Our unique warm compaction method allows us to produce low-cost, high-strength sprockets by increasing the density of low-alloy materials.

Outstanding “Sprocket” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

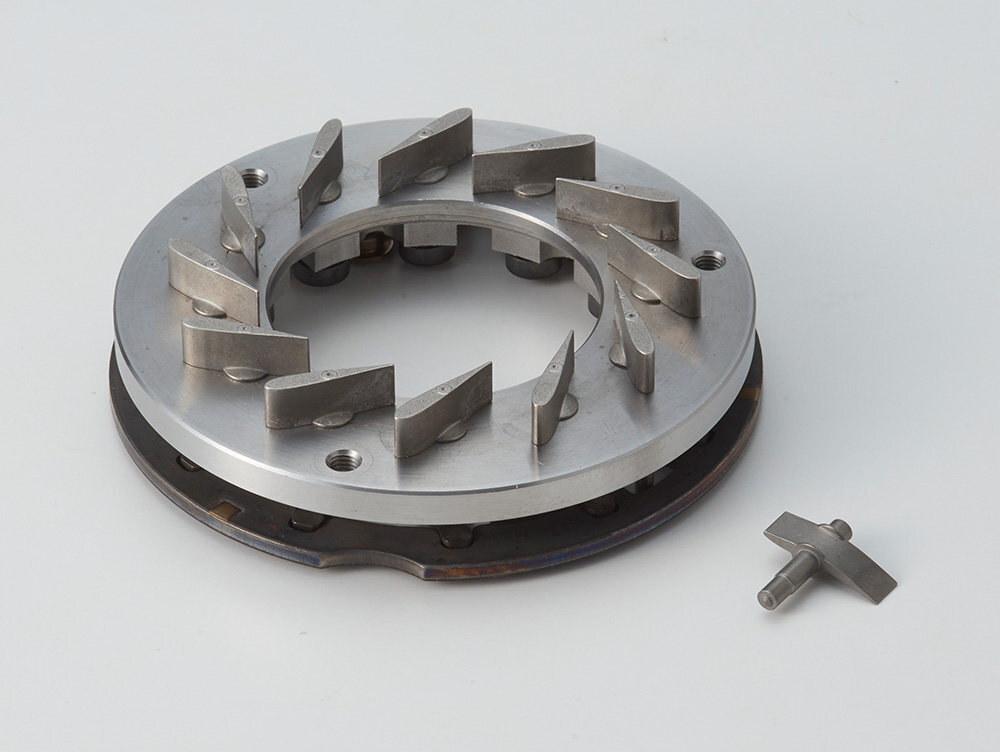

Vane Nozzle

- Automotive Parts

- Engine Parts

Using stainless steel materials that can withstand use in high-temperature exhaust air, we manufacture complex three-dimensional shapes by the MIM (metal injection molding) method.

Outstanding “Vane Nozzle” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Spherical Seat

- Parts for Industrial Machinery

Outstanding “Spherical Seat” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Shaft eccentric

- Automotive Parts

- Engine Parts

Even with complex and thin-walled shapes, high dimensional accuracy is ensured.

Outstanding “Shaft eccentric” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Sprocket

- Automotive Parts

- Engine Parts

The tooth tips are highly strengthened by induction hardening, and the tooth shape is formed by a near-net-shape manufacturing technique.

Outstanding “Sprocket” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Housing

- Automotive Parts

- Engine Parts

Complex inner profile shapes are formed by a near-net-shape manufacturing technique that is unique to powder metallurgy.

Outstanding “Housing” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Flange

- Parts for Industrial Machinery

This part is manufactured by the MIM (metal injection molding) method. The use of MIM process has realized a significant cost reduction in parts that were conventionally manufactured by machining.

Outstanding “Flange” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Rotor

- Automotive Parts

- Engine Parts

Complex outer profile shapes are formed by a near-net-shape manufacturing technique that is unique to powder metallurgy.

Outstanding “Rotor” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Sintered Arm

- Automotive Parts

- Engine Parts

High-precision helical splines are realized with high technical capability. The processing cost has been reduced by processing green compacts.

Outstanding “Sintered Arm” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes