Powder Metallurgy Products

- Top

- Business

- Powder Metallurgy

- Powder Metallurgy Products

Search products

Automotive parts

Drivetrain Parts

Other Automotive Parts

Product list of Induction Hardening

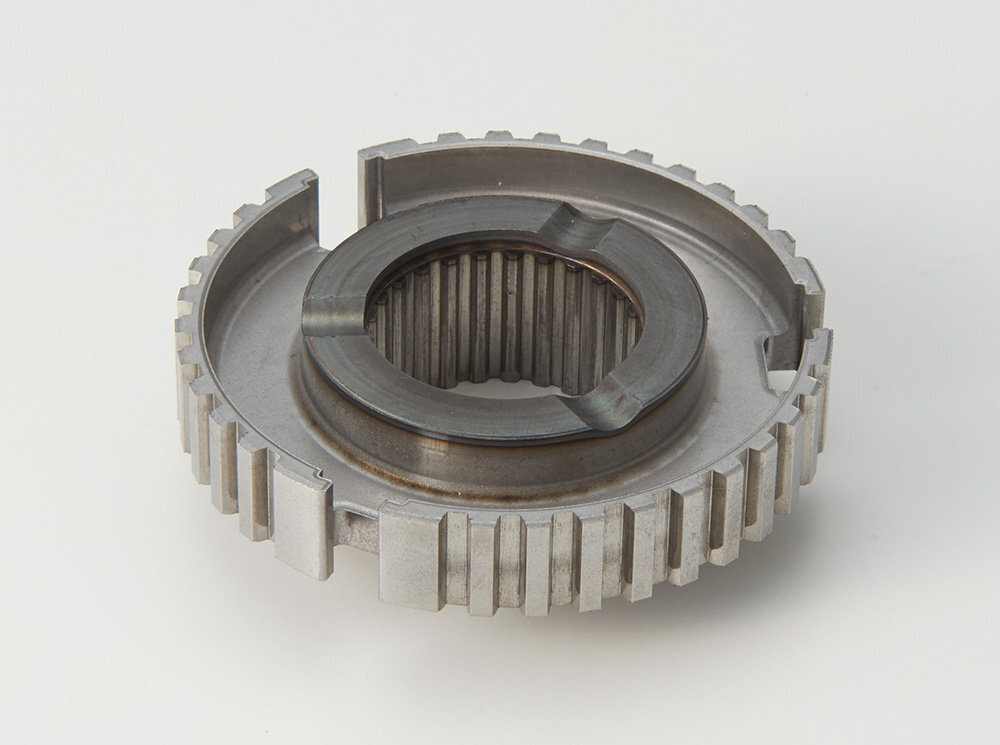

Hub

- Automotive Parts

- Drivetrain Parts

The deep concavo-convex surfaces and complex profiles are formed by net shape processing using a CNC press, contributing to reduction in raw materials and costs.

Outstanding “Hub” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Sprocket drive

- Automotive Parts

- Drivetrain Parts

The sprocket is attached to the chain that connects the AT spindle and oil pump shaft.

In addition to high-precision, multi-stage gear sprockets, we mass produce sprockets using our original technologies such as batch induction hardening and tempering of multi-stage gears and phrasing processes.

Outstanding “Sprocket drive” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

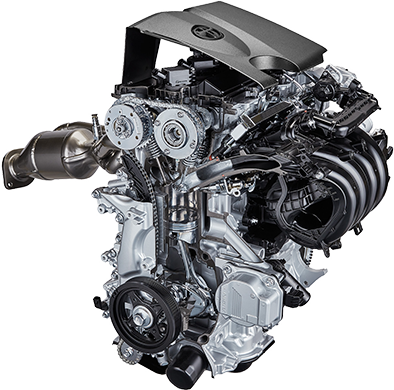

Sprocket

- Automotive Parts

- Engine Parts

Our unique warm compaction method allows us to produce low-cost, high-strength sprockets by increasing the density of low-alloy materials.

Outstanding “Sprocket” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes

Sprocket

- Automotive Parts

- Engine Parts

The tooth tips are highly strengthened by induction hardening, and the tooth shape is formed by a near-net-shape manufacturing technique.

Outstanding “Sprocket” Features!

Material

Heat Treatment

Flexibility in Shapes

Surface Treatment

Joining Technique

Composite Material

Special Processes